목표 : 3월 28일에 CPIM Part 1 취득하기

301. the purpose of ABC analysis and control is that items need tight control.

302. trucks as a mode of transportation, are best suited for moving small quantities to widely dispersed markets.

trains are better for moving large quantities.

303. 계산 문제

304.계산 문제

305. the inventory turns ratio measures how effectively inventories are being used. it is calculated by dividing annual cost of goods sold by average inventory in dollars. (매출원가/ 평균 재고액)

306. with intermittent manufacturing, the flow of work is varied, depending on the design. this causes the work flow to be unbalanced. machinery and workers need to be flexible and are generally grouped together by function. throughout times are generally long depending on the work which needs to be done at each work center. as a result, scheduling is very complex. the capacity needed depends on the mix of products moving through the various work center.

[CPIM교재] Section B. MANUF.. : 네이버블로그 (naver.com)

[CPIM교재] Section B. MANUFACTURING DESIGN, PLANNING, AND CONTROL

Section B: Manufacturing Design, Planning, and Control 앞서 배운 기업 전략에서 manufacturing이...

blog.naver.com

307. fixed lcation warehouses offer poor cube utilization becuase pallet location are left empty when the product assigned to the location is out of stock. generally, fixed locations are used in small warehouses with low throughput.

308. senior management should be the first to receive education on total quality management concepts.

309. when each distribution center orders from central supply of the factory independently of what other distribution center are doing, it is called a pull system. the advantage is that coordination and communication is less expensive. the disadvantage is that the lack of coordination causes probelms with customer service and inventories.

310. releasing orders to the shop controls the input rate. if orders are released faster than they can be produced, then queue, work-in-progress, and lead times will increase.

311. truckers, airline and water carries accept less than full load, but railways usually do not accept LCL(less than carloads) shipment. transportation costs can be decreased by using warehouses. this is accomplished by consolidating small shipment into large shipments. it means that LTL shipement from several suppliers can be consolidated at warehouse before bing shipped TL to the factory.

312. as a company increases the number of warehouses from one to two, safety stock will increase and the percent can be calculated.

the amount of the increase will depend on service levels by part, the demand variation, and other factors. as the number of warehouses increases, demand at each will decreas, causing greater variation in product demand. therefore, safety stock will increase appropriately.

313. the master production schedule is the anticipated build schedule for those items assigned to the master schedult.

314. anticipation inventory provides a buffer for seasonal demand.

315. 계산 문제

316. an intermittent manufacturer is characterized by processing in batches, and large variation in design and order quantities. at the extreme, every job could be made to customer specifictaion. the product lacks a continuous flow. howver, JIT principle can be applied for employee involvement, workplace layout, total quality control, preventive maintenance, setuptime redution, supplier partnership, and inventory reduction.

317. standard time, measured as larbot hours, can be used as the common measure of output and work content.

it can be used for loading and scheduling.

318. overloaded work centers determines the throughput of a munufacturing process.

work center에 overload되었으니 이 work center가 bottle neck이 되고 bottle neck이 되는 work center가 throughput을 결정 한다.

319. the purpose of grouping item in a warehouse is to be more productice in storage and in the picking process. items which have sequential SKU numbers may have nothing to do with each other.

a basic grouping methods to store and locate stock in a ware house are

1) items related functionally

2) items which are physically similat

3) items which are fast moving

320. the followings would be included in demand management.

- forecasted requirements

- service parts requirements

- branch warehouse requirements

- inter-plant orders

service part is independent item

service parts would typically be forecast independetly from their use during the manufacture of the jet engine. therefor, the jet engine might have independent and dependent demand.

321. backflushing is a system for doing inventory and labor transactions based on the finished goods production. with this system, one transaction will create the many issues transaction for inventory. this process works best when the leadtime for the product is short and the product flow down a product line.

322. a lot for lot ordering rule will order just the amount needed based on the net requirement.

323. 계산 문제

324. while strategic plans do provide for manufacturing, sales and new product plane, they really provide the overall direction for the company. the result is a statement of goals and objectives for 2~5 years and sometimes 10.

325. physical distribution includes the activities of transportation, distribution, inventory, warehousing, material handling, packaging, and order processing.

326. in a decentralized distribution system, the role of the central supply organization is to repspond to demands fromt the distribution centers.

327. firm planned orders will reduce system nervousness, especially inside the manufacturing lead time. the planner could ignore the exception messages, however, this could become a dangerous practice.

328.

cost of carrying inventory = capital cost, storage cost, risk cost(obsolescence,damage, pilferag, deterioration), opportunity cost

* the mose significant cost factor that contributes to inventory carrying cost is opportunity cost.

cost of ordering : production control cost, setup and tear down cost, lost capacity cost(ordering에 쓴 capcacity를 잃는 거니까 오더링 하는 순간, purchase oder cost

inventory carrying cost 기여하는 것중 에서 가장 중요한 cost factor는 ? : 네이버 카페 (naver.com)

329. inputs to the material requirement planning system are

1) MPS 2) Inventory record 3) BOM.

MPS drives the MRP system by providing the initial input for the items needed.

a major input to the MRP is inventory. when a calcultaion is maed to find out how many are needed, the quantities available must be considered. the BOM shows all the part required to make one of them.

330. deivery time is defined as the time elapsed between receipt of the customer's order and the delivery to the customer. engineer to order companies have the longest delivery time due to the engineering which must occur before the product can be manufactured for delivery.

331. the planner / buyer concept improves coordination between the factory and supplier.by elminating the extra handoff between planner and buyer, communication will improve. while material will flow more smoothly into the facility, the flow through the factory is depended on many other factors.

332. cycle stock is one of the two main conceptual components of any inventory, the cycle stock is the most active component, i.e, that which depletes gradually as customer orders are received and is replenished cyclically when supplier order are received.

333. MRP has two major objectives; determine requirements and keep priorities current. MRP is to determine what components are needed to meet the master production schedule and based on leadtime, to calculate the periods when component must be available. in the ever-changing world, MRP must be able to reorganize priorities to keep plans current.

334. physical supply/distribution include all the activities involved in moving goods, from the supplier to the beginning of the production process, from the end of the production process to the consumer. the activities involved are transportation, distribution inventory, warehousing, packaging, material handling, order entry etc.

335.

336. the required factor in selecting a supplier are technical ability, manufacturing capability, reliability, service after sale, supplier location and price.

337 normal distribution refers to the statical distribution of values where the majority of values will accumulate around the mean. the resulting graph is shaped like a bell. it is often known as bell curve.

338. offsetting is the process of placing the exploded requirements in their proper periods based on leadtime.

- offsetting : 앞단계에서 전개된 수요량에 대해 기간별로 그 양을 기재(입력)하는 과정 (리드 타임을 고려한다, LT에 맞게 planned order release에 배치하는 것)/ bom의 하위자재들이 각각의 leadtime 기준으로 일정이 만들어 지는 개념.

- expliding : 필요한 component가 얼마나 되는 지 계산하는 과정. requirement를 구하는 과정.(수량을 multiple)/enditem의 소요일에 따라 bom이 전개되는 개념.

339. 계산 문제

340. quality must be the operators responsibility. they are the only one who can make sure defects are not built into the product. they must be allowed to stop process when defects are found.

341. in the periodic review systme, the review period is fixed, and the order quantity is allowed to vary. the system requires a larger inventory to cover the maximum expected demanding during the leadtime plus a review interval.

342. make to stock companies ship customer order from finished goods.

343. input/output control manages the queues by regulating the flow of work into the work center. by regulating the inflow of work to equal the outflow of work. the work will flow smoothly to meet the leadtimes needed. generally, the input/output control is measured in hours.

344. relatively small quantities of working stock can be located close to the marshalling and shipping area whereas reserve stock used to replenish the working stock can be located more remotrly. this allows order picking to occur in a compact area and replenishment of the working stock in bulk by pallet or container load.

345. 계산 문제

346. the pareto analysis is used to rank the frequency of problems.

347. the most critical in achieving the goal of value added is the materials, and labor is the least imporant usually.

348.계산 문제

349.계산 문제

(1) Marshalling Area In Warehouse? | LinkedIn

Expliding, offseting 이해 : 네이버 카페 (naver.com)

'스터디스터디 > CPIM' 카테고리의 다른 글

| 350제 - 계산문제 (0) | 2023.03.24 |

|---|---|

| 350제 - 헷갈린거 정리 (0) | 2023.03.24 |

| [Completed]350제 - 3 (1) | 2023.03.23 |

| [Completed] Pocket prep -1(50/100) (0) | 2023.03.21 |

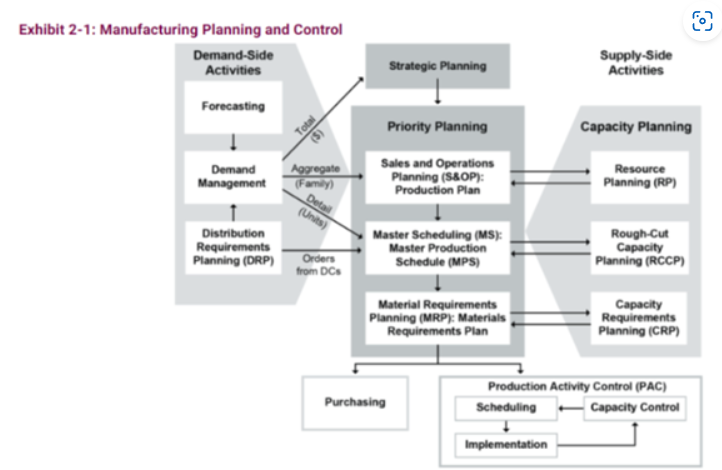

| [Completed]350제 - 2 (1) | 2023.03.21 |